We are the mind that creates and the strength that produces

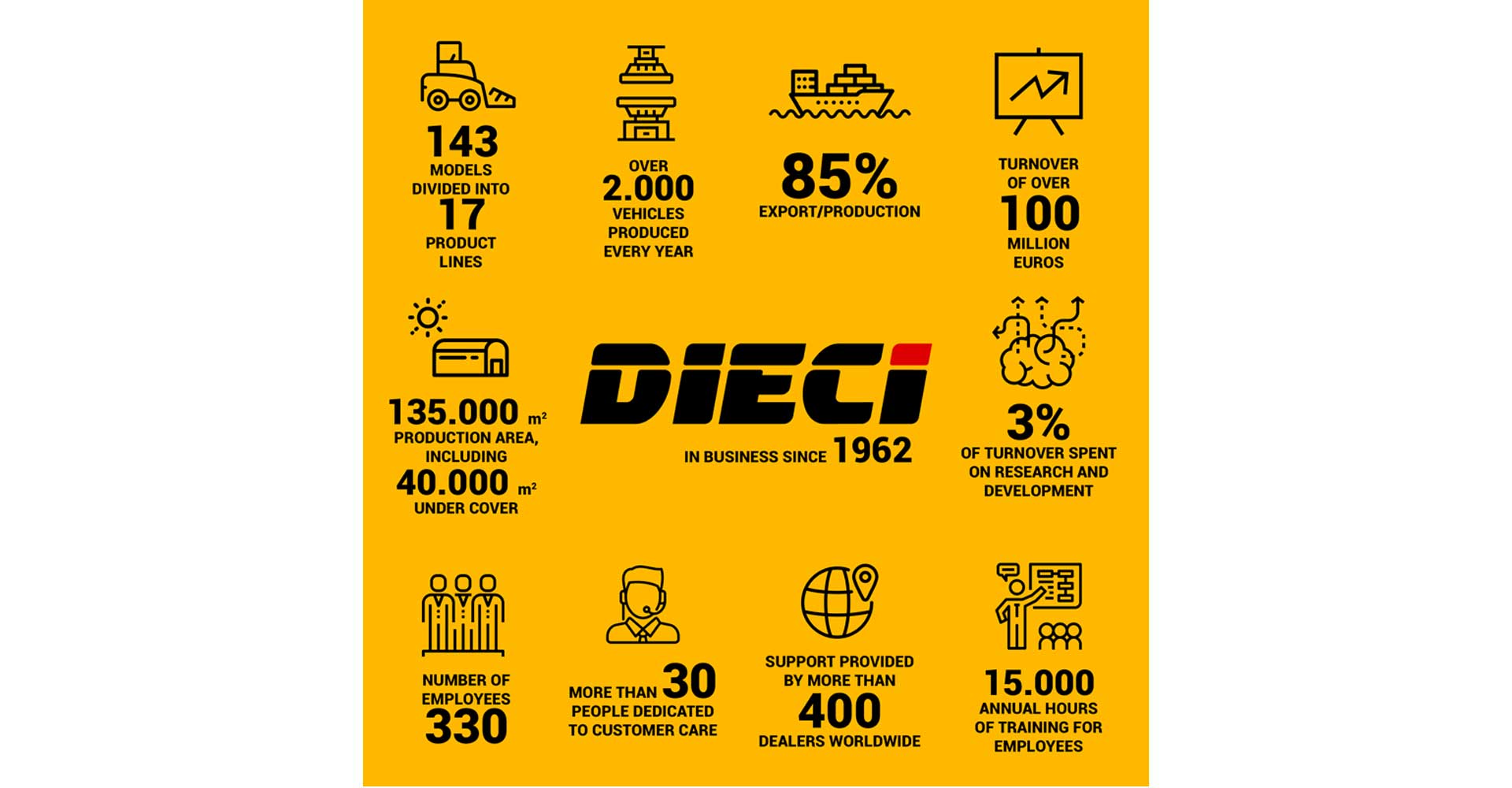

We started out in 1962 by designing and building concrete mixers and in 1983 we were one of the first European manufacturers to develop and produce a range of telehandlers. Our offering has continued to expand over the years: in 1998 we presented the S.I.R. telehandler series — Samson, Icarus and Runner.

In 2000 we unveiled the now well-known Pegasus family of telehandlers with 360- and 400-degree rotating boom, and in 2021 the Pegasus Rotational line-up was completely reengineered to encompass the Essential, Classic and Elite classes. More recently we launched HERCULES, the new line of high load capacity vehicles for heavy industry, as well as the AGRI Mx Power X2 and soon to come all new Hybrid units for Agriculture Telehandlers, which are specially designed for intensive agricultural use. Added to this is the Agri Pivot range of wheel loaders with telescopic boom.

Dieci Americas Telehandlers was formed in mid 2014 to respond to the demand of the US market due to the growth of the Dieci brand. Dieci Americas is the single source for all Dieci products distributed in the Americas and is managed by a seasoned equipment team. Lead by Ken Vaow and Kevin Cook, Dieci Americas Telehandlers has already made a significant impact meeting our customers needs for advanced machines and providing a support system for all Dieci products in the Americas.

For more information on how Dieci Americas Telehandlers can meet your needs please Contact Us or visit our Registration page to register your Dieci product.

Dieci has been manufacturing best-in-class construction and agricultural equipment since 1962 and has been producing telescopic handlers for over 31 years. Dieci machines are manufactured with extremely heavy-duty boom sections and main frames and are designed to handle the abuse associated with continuous, duty-cycle bucket use where others fail. The visibility and safety features are the best in the industry. The broad Dieci telehandlers product line includes over 75 base models / over 140 model variations, ranging from 5,500 lb. lift capacities through 50,700 lbs., with lift heights reaching as high as 114 feet.

Dieci also offers four models of off-highway concrete mixer trucks and four models of site dumpers.

We are the continuous innovation of our business approach

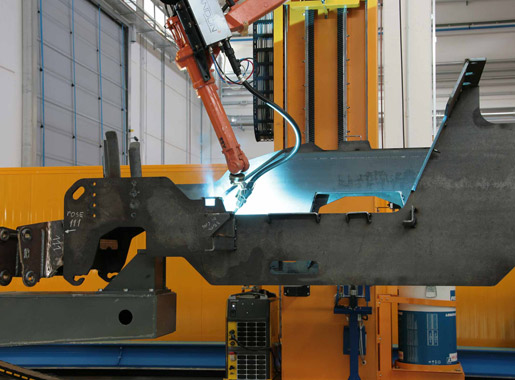

In order to progressively implement our technology solutions, our production processes, and our vocational training, we launched the Kaizen Project—inspired by the Japanese philosophy of continuous improvement—in order to eliminate waste and inefficiency. In line with this approach that reflects the most modern organizational standards, a radical change is underway that will increase productivity and quality while eliminating activities that do not create added value for the company and its customers.

To achieve this objective, DIECI is completely overhauling its production processes so as to simplify and streamline the management of the various tasks. The nine existing assembly lines and their complementary departments will converge into a new model based on six “integrated flow channels”, which will output the finished products ready for shipment.

We are the guarantee and the reassurance of always being there

Throughout its more than 50 years in business, DIECI has focused on constantly researching innovative technologies in the agricultural, industrial, construction and special vehicles sector, as well as on providing excellent pre-sales and after-sales service.

This strategy has enabled the company to establish itself as one of the most important players in the global industry, with over 85% of its vehicles sold abroad through four European subsidiaries: DIECI Deutschland GmbH in Germany, DIECI Telehandlers in the UK, DIECI France in France and DIECI Vostok in Moscow, Russia.

This organisational structure, headquartered in Montecchio Emilia in the Emilia-Romagna region of Italy, is flanked and supported by a pervasive international network of distributors and accredited service centres in leading markets such as the United States, Canada, Central and Latin America, Turkey, the Middle East, South Africa and Australia.

We are the quality and reliability of our products

In order to ensure that all our vehicles—whether standard or special—are reliable and durable over time, we perform thorough testing under real operating conditions to evaluate their performance and their compliance with all of the design specifications, safety requirements imposed by regulations, homologation and certification parameters, and the characteristics required by the market. We carry out these checks using a testing ground, which is an area of over 20,000 m2 with a 900-metre concrete track, an off-road test course and a 400 m2 covered structure housing educational workshops, classrooms for training operators and a 60-seater grandstand with full views over the complex.

We also use special equipment such as a roller bench for performing tests in motion, a tilting platform for stability tests and electronic instruments, which capture the data needed for each vehicle’s development and implementation.

Products

We offer a comprehensive line of vehicles capable of satisfying users’ every application requirement. Few producers in the world are able to offer such a varied range with best-in-class performance in terms of productivity and reliability.

Services

From research and design to post-sale maintenance and support, a joint effort is needed that brings together the best technicians and engineers with a network of accredited suppliers and dealers. This close teamwork delivers concrete answers and comprehensive support.

People

The total satisfaction of all our customers is the initial intent and final objective of all our projects. This commitment, shared by all the people who work in our company, is essential to our way of doing business.